Husqvarna 125B Blower Manual: A Comprehensive Guide

This manual provides essential instructions for safe and effective operation of your Husqvarna 125B blower; read it carefully before use, starting 01/27/2026.

The Husqvarna 125B is a powerful and versatile handheld blower designed for residential and light commercial use. This manual serves as a comprehensive guide, ensuring users understand proper operation and maintenance procedures, effective as of 01/27/2026. Husqvarna continually improves its products, reserving the right to make changes without prior notice.

This blower is intended solely for the tasks outlined within this manual; misuse could lead to damage or injury. Operators must thoroughly read and understand all safety precautions and operating instructions before initial use. Access to support, spare parts, and guides is readily available online, enhancing the user experience and product longevity.

Safety Precautions and Warnings

Prior to operating the Husqvarna 125B blower, carefully review all safety precautions detailed in this manual, effective from 01/27/2026. Operators must fully understand the contents to prevent potential hazards. Never operate the blower without reading and comprehending these vital instructions.

Avoid wearing loose clothing or jewelry that could become entangled. Ensure a firm grip and stable footing during operation. Be mindful of bystanders and maintain a safe operating distance; Husqvarna AB emphasizes responsible use and adherence to all safety guidelines. Failure to follow these warnings may result in serious personal injury or property damage. Always prioritize safety when using this product.

Understanding the Components

Familiarizing yourself with the Husqvarna 125B blower’s components is crucial for safe and efficient operation, as of 01/27/2026. This section details the key parts, including the blower housing and fan, responsible for generating airflow. The engine and carburetor system control power and fuel delivery.

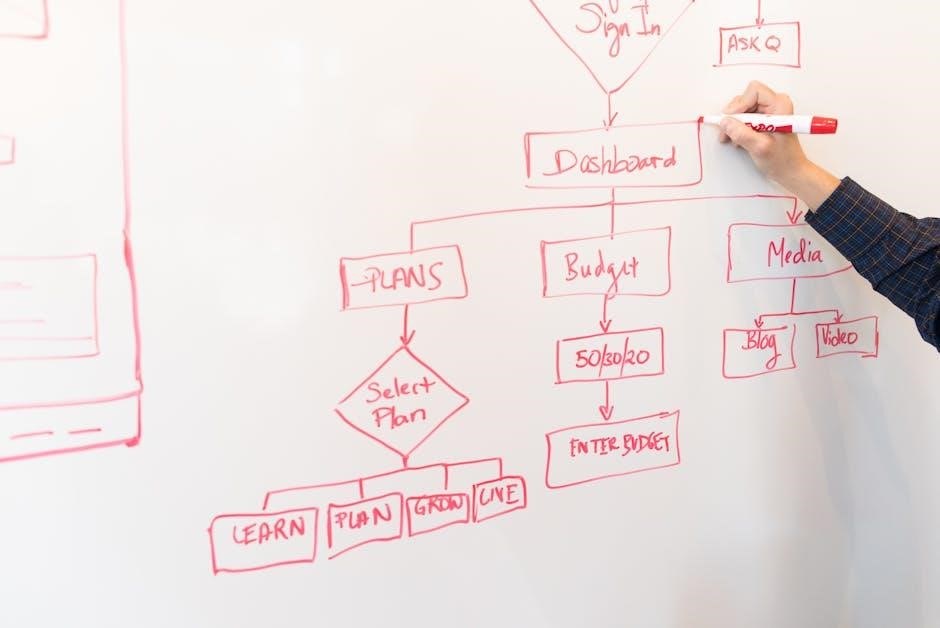

Additionally, we’ll cover the handle and controls, outlining their functions for starting, stopping, and directing the airflow. Understanding how each component interacts ensures proper maintenance and troubleshooting. Refer to this manual for detailed diagrams and explanations. Husqvarna AB designs for user understanding and optimal performance, so knowing your blower is key.

Blower Housing and Fan

The Husqvarna 125B’s blower housing is engineered to maximize airflow and direct it efficiently. Inside, the fan, driven by the engine, creates the powerful air stream necessary for moving leaves and debris, as of 01/27/2026. Regularly inspect the housing for cracks or damage, as these can reduce performance and pose safety risks.

Ensure the fan blades are free from obstructions and in good condition. A damaged fan can become unbalanced, causing vibration and potential component failure. This manual emphasizes the importance of maintaining these parts for optimal blower function. Husqvarna prioritizes durable design, but regular checks are vital.

Engine and Carburetor

The Husqvarna 125B is powered by a two-stroke engine, requiring a precise fuel-to-oil mixture for optimal performance, as of 01/27/2026. The carburetor mixes air and fuel, delivering it to the engine. Proper carburetor function is crucial for easy starting and consistent power. This manual details the correct fuel mixture ratio – always adhere to these specifications.

Regularly inspect the carburetor for clogs or debris, which can affect engine operation. Husqvarna recommends using fresh fuel and a fuel stabilizer to prevent issues. Understanding the engine and carburetor system, as outlined in this guide, ensures longevity and efficient operation of your blower.

Handle and Controls

The Husqvarna 125B blower features an ergonomic handle design for comfortable operation, effective as of 01/27/2026. Key controls include the throttle trigger, which regulates engine speed and blowing force. A stop switch immediately halts the engine. Familiarize yourself with the location and function of each control before operating the blower, as detailed in this manual.

The handle also incorporates vibration dampening to reduce operator fatigue during extended use. Husqvarna prioritizes user comfort and safety. Always maintain a firm grip on the handle during operation. Proper understanding of the handle and controls ensures safe and efficient operation of your 125B blower.

Assembly Instructions

Before first use, some minor assembly of your Husqvarna 125B blower is required, effective as of 01/27/2026. Carefully unpack all components and verify that all parts listed in this manual are present. Typically, assembly involves attaching the handle to the blower housing using the provided screws and fasteners. Ensure all connections are secure before operation.

Refer to the detailed diagrams within this manual for proper alignment and fastening procedures. Do not overtighten screws, as this could damage the components. If you encounter any difficulties during assembly, consult the Husqvarna support resources. Correct assembly is crucial for safe and optimal performance of your blower.

Starting and Stopping the Blower

To start your Husqvarna 125B blower (updated 01/27/2026), ensure the unit is on a level surface and the air filter is clean. Prime the fuel bulb several times, then engage the choke. Pull the starter cord firmly and repeatedly until the engine ignites. Gradually disengage the choke as the engine warms up.

To stop the blower, simply release the throttle and allow the engine to idle briefly before pressing the stop switch. Never abruptly disconnect the spark plug wire while the engine is running. Always follow these instructions for safe operation. Refer to the manual for detailed diagrams and troubleshooting tips.

Operating Instructions

When operating your Husqvarna 125B blower (as of 01/27/2026), maintain a safe distance from people and objects. Always wear appropriate safety gear, including eye and hearing protection, as detailed in the manual. Begin with a low throttle setting and gradually increase as needed. Avoid directing the airflow towards bystanders or sensitive areas.

Proper blowing techniques involve sweeping motions, working with the wind whenever possible. Regularly check for debris ingestion and clear the intake screen. Adhere to all safety instructions outlined in this guide. Remember, the operator must understand the manual’s contents for safe and efficient use.

Proper Blowing Techniques

Effective operation of your Husqvarna 125B blower, referencing the manual (updated 01/27/2026), relies on strategic techniques. Utilize sweeping motions, overlapping each pass to avoid leaving debris behind. Work with the wind direction for maximum efficiency, minimizing re-scattering. Maintain a consistent speed and distance from the surface being cleared.

Avoid creating dust clouds by adjusting the blower’s angle and speed. For stubborn debris, a slightly lower nozzle position and increased airflow may be necessary. Always prioritize safety, adhering to all instructions and keeping bystanders clear. Regular checks for intake blockage are crucial for optimal performance.

Adjusting Blower Direction

The Husqvarna 125B blower’s nozzle allows for directional control, detailed in the manual (current as of 01/27/2026). Rotate the nozzle to precisely target debris, maximizing clearing efficiency. A wider spread is ideal for large areas, while a focused stream tackles stubborn leaves or heavier materials.

Ensure the nozzle is securely locked in the desired position before operation. Experiment with different angles to find the most effective approach for various surfaces and debris types. Remember to follow all safety instructions while adjusting the blower’s direction, keeping clear of obstructions and bystanders. Proper adjustment minimizes effort and maximizes cleaning power.

Maintenance Schedule

Regular maintenance, as outlined in this Husqvarna 125B blower manual (updated 01/27/2026), is crucial for optimal performance and longevity. After each use, inspect for loose screws and damage. Clean the blower housing thoroughly, removing any accumulated debris.

Every 25 hours of operation, clean or replace the air filter to ensure proper engine function. Check the spark plug and replace it annually, or as needed. Periodically inspect the fuel system for leaks or blockages. Following this schedule, detailed in the manual, will help maintain peak efficiency and prevent costly repairs. Refer to the instructions for specific procedures.

Air Filter Cleaning

Maintaining a clean air filter is vital for your Husqvarna 125B blower’s performance, as detailed in the manual (current as of 01/27/2026). A dirty filter restricts airflow, reducing power and potentially damaging the engine. After every 25 hours of operation, or more frequently in dusty conditions, remove the air filter.

Tap it gently to dislodge loose debris. For paper filters, blow clean from the inside out with low-pressure compressed air – never use water. Foam filters can be washed in mild soap and water, then allowed to dry completely before re-oiling lightly. Always refer to the manual’s instructions for proper filter installation and replacement;

Spark Plug Replacement

The Husqvarna 125B blower’s spark plug requires periodic replacement, as outlined in the manual (updated 01/27/2026), to ensure optimal engine performance. A worn spark plug can cause hard starting, misfiring, and reduced power. Consult the manual for the correct spark plug type.

Disconnect the spark plug wire before removal. Use a spark plug wrench to carefully unscrew the old plug. Check the gap of the new spark plug using a feeler gauge, adjusting if necessary to the manual’s specifications. Install the new plug, tightening it securely but not over-tightening. Reconnect the spark plug wire, and you’re ready to go!

Fuel System Maintenance

Maintaining the Husqvarna 125B blower’s fuel system, as detailed in the manual (dated 01/27/2026), is crucial for reliable operation. Use fresh fuel and a fuel stabilizer to prevent gum and varnish buildup. Regularly inspect the fuel lines for cracks or leaks, replacing them if damaged.

The manual recommends cleaning the fuel filter periodically. Before any fuel system work, always disconnect the spark plug wire for safety. If the carburetor requires cleaning, follow the manual’s specific instructions carefully. Proper fuel system maintenance ensures consistent power and extends the life of your blower.

Troubleshooting Common Issues

This section, referencing the Husqvarna 125B blower manual (current as of 01/27/2026), addresses frequent problems. If the engine won’t start, check the fuel level, spark plug, and air filter – consult the manual’s detailed instructions. A loss of power often indicates a clogged air filter or stale fuel; cleaning or replacing these components is vital.

Refer to the manual for specific diagnostic steps. Always disconnect the spark plug before performing any maintenance. If issues persist, consult Husqvarna support or a qualified technician. Ignoring problems can lead to further damage; proactive troubleshooting, guided by the manual, saves time and expense.

Engine Won’t Start

If your Husqvarna 125B blower’s engine fails to start (as of 01/27/2026, per the manual), begin by verifying sufficient fuel and ensuring the fuel valve is open. Next, inspect the spark plug for fouling or damage; a replacement might be necessary, following the manual’s guidance. A clogged air filter restricts airflow, hindering ignition – clean or replace it.

Confirm the choke is properly engaged for cold starts, and the throttle is set correctly. Refer to the manual’s detailed instructions for priming the carburetor. If these steps fail, consult the troubleshooting section within the manual or contact Husqvarna support for further assistance.

Loss of Power

Experiencing reduced blowing force with your Husqvarna 125B (updated as of 01/27/2026, according to the manual)? First, check the air filter for obstructions; a dirty filter significantly restricts airflow, causing power loss. Inspect the spark plug – fouling or damage can weaken the ignition. Ensure fresh fuel is being used, as stale fuel diminishes engine performance.

Verify the carburetor isn’t clogged, potentially requiring cleaning or adjustment as detailed in the manual’s instructions. A partially blocked fuel line can also limit fuel delivery. If the issue persists, consult the manual’s troubleshooting guide or contact Husqvarna support for expert assistance.

Technical Specifications

The Husqvarna 125B blower, as detailed in the manual (current as of 01/27/2026), boasts a displacement of 28.2 cc and a fuel capacity of 0.5 liters (17 fl. oz.). Its engine delivers a power output of 1.1 kW (1.5 hp). The air volume reaches 170 CFM (cubic feet per minute), with a maximum air velocity of 170 mph.

The blower weighs approximately 9.9 lbs (4.5 kg), ensuring manageable operation. Sound power level is 99 dB(A), requiring hearing protection. Fuel mix ratio is 50:1 (gasoline to 2-stroke oil). Refer to the complete manual for detailed specifications and safety instructions regarding operation and maintenance.

Husqvarna Support and Resources

For comprehensive support regarding your Husqvarna 125B blower, and referencing the manual updated on 01/27/2026, visit the official Husqvarna website. There, you’ll find downloadable manuals, frequently asked questions, and troubleshooting guides. Access to genuine spare parts and accessories is also available online.

Customers can locate authorized service dealers through the website’s dealer locator tool. Husqvarna provides detailed how-to videos demonstrating maintenance procedures. For direct assistance, contact Husqvarna customer support via phone or email, details of which are included within the product manual. Ensure you have your model number ready for efficient support.

Warranty Information

Husqvarna AB, located in SE 561 82 Huskvarna, Sweden, provides a warranty for the 125B blower, detailed within the product manual as of 01/27/2026. The warranty covers defects in materials and workmanship under normal use, beginning from the original purchase date.

Warranty duration varies based on region and product registration. It’s crucial to register your 125B blower to ensure full warranty coverage. The warranty does not cover damage resulting from misuse, improper maintenance, or unauthorized repairs. Refer to the complete warranty statement included with your manual for specific terms, conditions, and claim procedures. Proof of purchase is required for all warranty claims.

Spare Parts and Accessories

Genuine Husqvarna spare parts and accessories for your 125B blower are readily available to maintain optimal performance, as of 01/27/2026. These include replacement air filters, spark plugs, fuel lines, and blower tubes. Utilizing genuine parts ensures compatibility and prolongs the life of your equipment.

Accessories, such as different nozzle attachments, can enhance the versatility of your 125B for various cleaning tasks. To locate authorized dealers and order parts, consult the Husqvarna support resources detailed in this manual or visit the official Husqvarna website. Always refer to the parts diagram within the manual when ordering to ensure correct fit and function.

Manual Updates and Revisions

Husqvarna AB continuously strives to improve its products, including the 125B blower, and reserves the right to make changes to specifications and design as of 01/27/2026. Consequently, this manual is subject to updates and revisions. It’s crucial to stay informed about the latest version to ensure safe and efficient operation.

Check the official Husqvarna website regularly for updated manuals, supplementary information, and potential safety notices pertaining to your 125B blower. Downloadable versions will be available, reflecting any changes made since the original publication. Always refer to the most current manual for accurate instructions and safety guidelines. Prior versions are superseded by newer releases.